- -8%

PEUGEOT 103

PEUGEOT 103 MBK 51

MBK 51 MOTOBECANE

MOTOBECANE PIAGGIO CIAO / VELOFAX

PIAGGIO CIAO / VELOFAX PEUGEOT FOX

PEUGEOT FOX HONDA CAMINO, PX, PXR...

HONDA CAMINO, PX, PXR... DERBI VARIANT

DERBI VARIANT.png) SOLEX

SOLEX PUCH

PUCH MINARELLI AM6

MINARELLI AM6 Low-pass exhaust pipe

Low-pass exhaust pipe High-pass exhaust pipe

High-pass exhaust pipe DERBI Euro 3 / 4 / 5

DERBI Euro 3 / 4 / 5 DERBI Euro 1 & 2

DERBI Euro 1 & 2 MINARELLI P4 & P6

MINARELLI P4 & P6.png) MINARELLI RV6, RV5, RV4, RV3

MINARELLI RV6, RV5, RV4, RV3 SUZUKI SMX, RMX, TSX

SUZUKI SMX, RMX, TSX YAMAHA TY, RD, DT, MX

YAMAHA TY, RD, DT, MX HONDA MB, MT, MTX, MBX, NSR R

HONDA MB, MT, MTX, MBX, NSR R YAMAHA CHAPPY

YAMAHA CHAPPYBanner

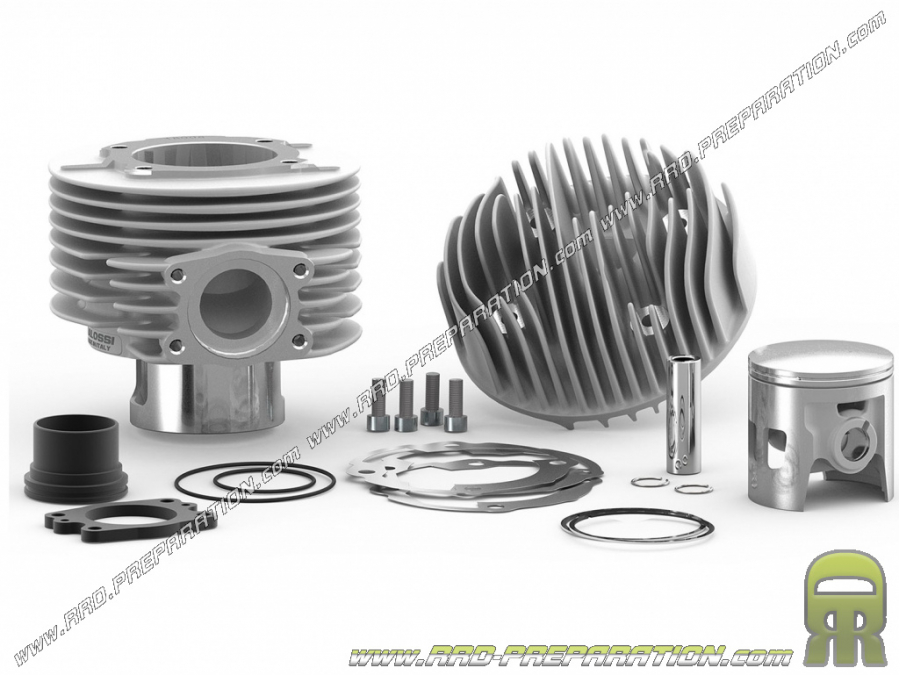

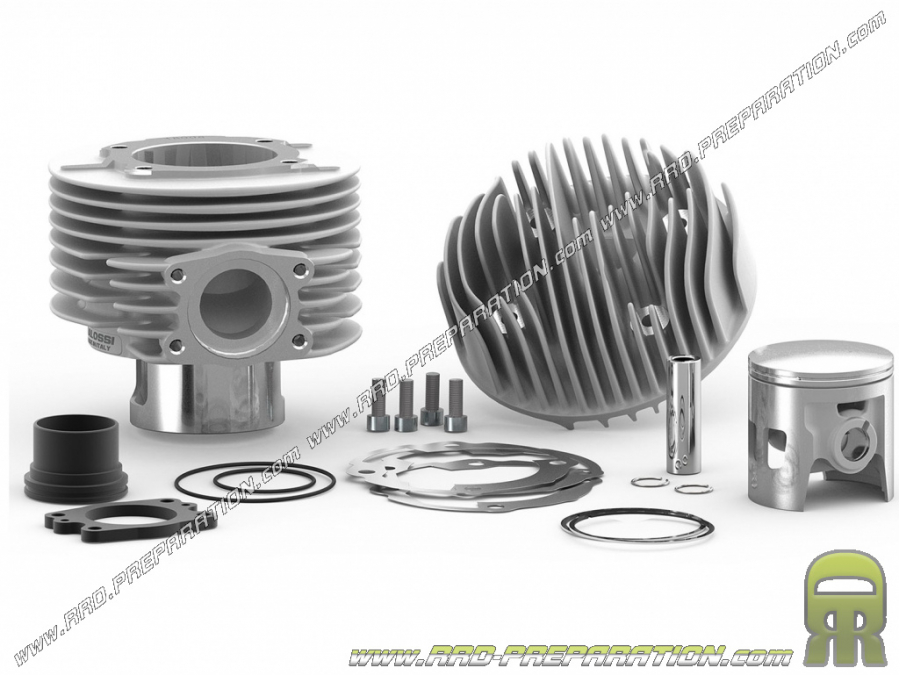

Here is the Ø63mm aluminum kit 177cc from malossi.

Entirely new, it was created to give the best result and an exemplary life. Every aspect of the system has been studied to optimize the mechanical resistance, the dynamics of the fluids and to improve the combustion

As far as the cylinder is concerned, it is made entirely of high-strength aluminum alloy and with a chromed nickel coated jacket. Composed of a central core with a constant thickness around the jacket and transfers, it guarantees a constant heat exchange, and therefore a controlled temperature of introduction of gases into the chamber and an optimal heat exchange at the exhaust; it has airfoil cooling fins around the core, designed for maximum efficiency of penetration of cooling air. The main innovation is represented by the completely revised and corrected transfer, introducing the Fast Fluids Cycle according to the latest innovations obtained thanks to the experience gained during the competitions. The transfers have been increased to the number of 7, which distinguishes the Malossi kit, thanks to which it has been possible to obtain the best performances in terms of fluid dynamics. The connection to the pot is made by a flange-fitting set attached to the cylinder by 4 cap screws and an O-ring at the exhaust inserted to prevent any leakage by the thermal group. This very simple mounting system guarantees the greatest resistance with the use of all pots with Ø 37 inlet that are on the market, avoiding any problem of unscrewing or rotation caused by the friction of the vehicle. On the other hand, the connection with the head is now performed through a high-precision centering on the support planes obtained with numerically controlled machines. A set of base seals with multiple thicknesses is provided to allow the user to adjust the compression by adopting it for the most varied uses.

The Ø15mm axis piston is fused with an innovative material, consisting of a steel core coated with an alloy of aluminum and silicon, which gives extreme lightness and excellent resistance to corrosion, even at high temperatures, and a reflection of the heat derived from the combustion, the heat flow is then conveyed to the dissipation surfaces, promoting cooling of the combustion chamber and maintaining the latter within the optimum temperature limits. It has, in the inner part of the coat, ribs embedded in the fusion which confer the right robustness in the most mechanically stressed areas, while allowing to lighten the piston as much as possible. On the other hand, the windows located on the rear part and the diametrical indentations guarantee the maximum possible flow of fresh air towards the transfers of the cylinders.

The cylinder head is equipped with profiled shalows according to modern simulations to allow the greatest possible penetration of the air coming from the cooling installation which touches the head with an increment of the yield of more than 10% compared to a traditional system to straight fins. The combustion chamber, with its hemispherical profile, has been machined with tolerances to the tenth of a millimeter and develops a high combustion. The combustion chamber, with a hemispherical profile, has been machined with tolerances to the tenth of a millimeter and develops a high combustion. turbulence, with pressure peaks calculated at the most appropriate regimes to achieve the best performance in terms of torque and power, the extremely high temperatures reached in this particular area of the head-to-cylinder boundary, which are often origin of hot spots and detonations, are resolved thanks to an aerospace solution

We recommend the installation of a carburetor Vhst 28, with the crankshaft stroke in 57mm , you will have a compression ratio of 1 : 10.8 , even more torque with its piston BI-SEGMENTS it will be advisable to couple it with a iw 27 candle

Mounts on :

LML STAR 125 2T

LML STAR 150 2T

VESPA COSA 125 2T

VESPA COSA 150 2T

VESPA PX 125 2T euro 0-1

VESPA PX 125 2T euro 2 (VLX2M)

VESPA PX 125 2T euro 3

VESPA PX 150 2T euro 0-1

VESPA PX 150 2T euro 2 (VLX2M)

VESPA PX 150 2T euro 3

Reference: 140.0084

The famous complete kit POLINI aluminum for VESPA 200cc 2T!

Reference: 3118005

Very high quality kit with great performance! Supercharged cylinder head, high diagrams ... Great performance for your Italian 2T scooter!

Reference: 63100.00

Kit right without cylinder head for your old RUMI Bi-cylinder 2T!

Reference: 57006.00

TOURING The kit is ideal for starting a simple configuration and performance with an aluminum cylinder.

Reference: KT00015

A very high performance and robust engine for your 125cc Vespa Primavera, ET3 ETS, PK, XL ...

Reference: 57010.00

148cc kit with admission valves W! Piston mono-segment, large diagrams, bar exhaust and intake 7 transfers! A kit with high performance central or lateral candle choices.

Reference: 140.0227

Very powerful kit at high speed! To be accompanied by a complete RACING configuration!

Reference: 3116346

Piston cylinder kit, aluminum cylinder head MALOSSI MHR for scooter VESPA COSA 200 2T and VESPA PX E 200 2T.

Reference: 57715.00

A high complete engine for guaranteed performance!

Reference: 57415.00

An absolutely huge kit! 195cc torque with a crankshaft race origin 57mm long rod 110mm!

Reference: 3111374

Ideal for increasing the performance of your 100cc 2-stroke scooter YAMAHA, MBK, APRILIA, BENELLI, ITALJET ...

Reference: KT00017

A large diameter high resistant motor drastically increasing engine capacity from 80 to 135cc!

Reference: 57940.00

The kit 144cc CHAMPION EUROPEAN COMPETITION VESPA 2015! Admission with flaps W, huge diagrams, two-part breech ...

Reference: 57022.00

The kit champion ITALIAN CUP 2015! Liquid, double roof valves, piston mono-segment, very thorough diagrams!

Reference: 140.0050/R

Improved Racing version, quality cast iron cylinder with high compression yoke for more performance!

Reference: 57058.00

The famous EVO SP 09, excellent performance! 60mm diameter for race origin 51mm with 97mm rod.