Reference: 486081

Engine housing silentblock Ø10x24x21mm common origin for PIAGGIO scooters and maxiscooter

Ideal in case of wear and vibration or for a refurbishment of your machine.

PEUGEOT 103

PEUGEOT 103 MBK 51

MBK 51 MOTOBECANE

MOTOBECANE PIAGGIO CIAO / VELOFAX

PIAGGIO CIAO / VELOFAX PEUGEOT FOX

PEUGEOT FOX HONDA CAMINO, PX, PXR...

HONDA CAMINO, PX, PXR... DERBI VARIANT

DERBI VARIANT.png) SOLEX

SOLEX PUCH

PUCH MINARELLI AM6

MINARELLI AM6 Low-pass exhaust pipe

Low-pass exhaust pipe High-pass exhaust pipe

High-pass exhaust pipe DERBI Euro 3 / 4 / 5

DERBI Euro 3 / 4 / 5 DERBI Euro 1 & 2

DERBI Euro 1 & 2 MINARELLI P4 & P6

MINARELLI P4 & P6.png) MINARELLI RV6, RV5, RV4, RV3

MINARELLI RV6, RV5, RV4, RV3 SUZUKI SMX, RMX, TSX

SUZUKI SMX, RMX, TSX YAMAHA TY, RD, DT, MX

YAMAHA TY, RD, DT, MX HONDA MB, MT, MTX, MBX, NSR R

HONDA MB, MT, MTX, MBX, NSR R YAMAHA CHAPPY

YAMAHA CHAPPYBanner

Description MALOSSI :

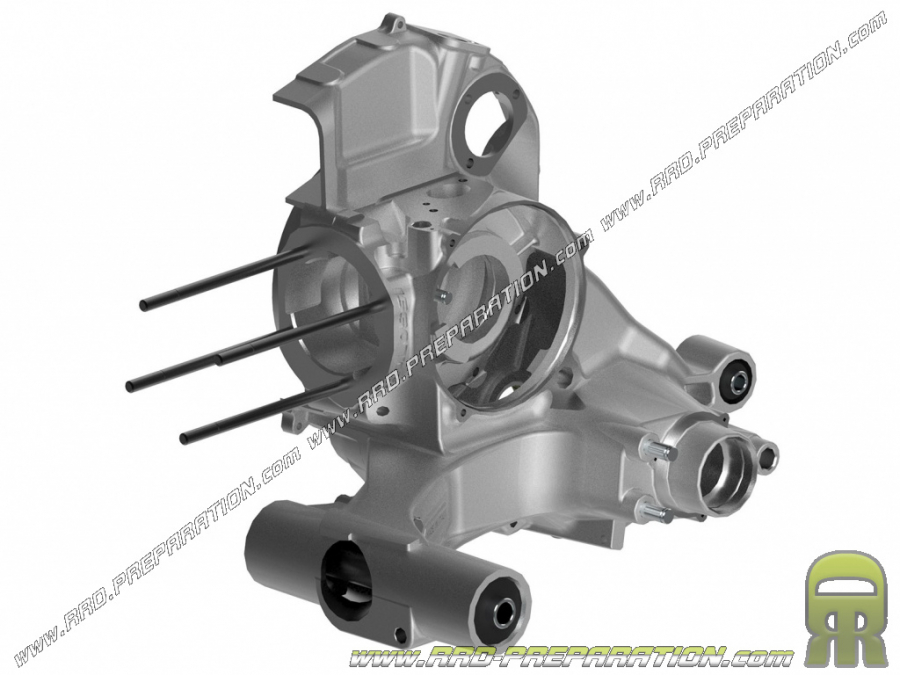

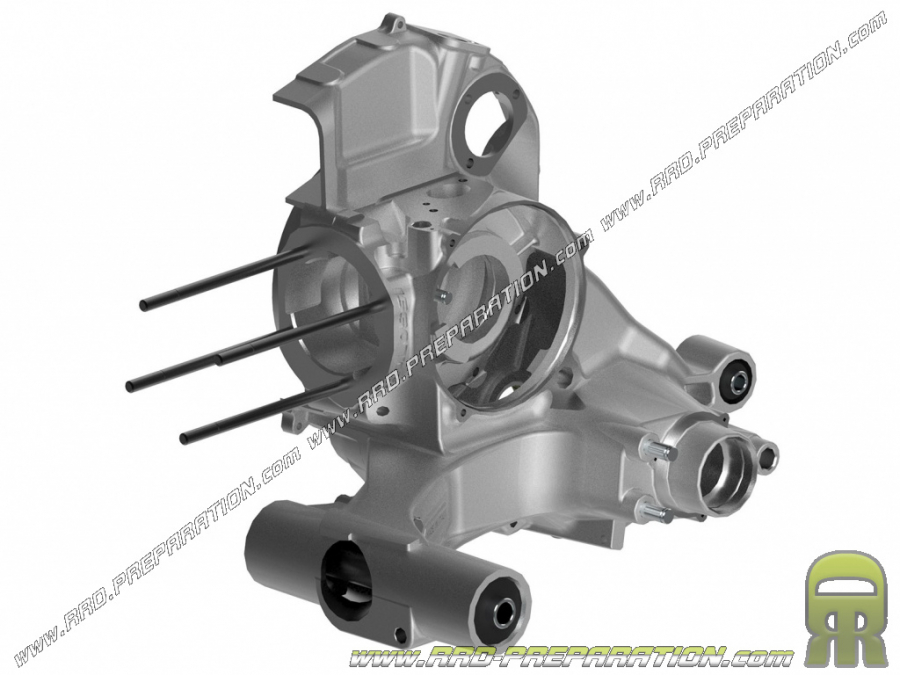

The V-One was designed for those who are looking for a housing that can perfectly replace the original, equipped with all the components necessary for assembly (see above) and allowing maximum interchangeability with components on the market. The V-One lends itself to both a complete restoration, as it does not require any modification to the vehicle and fits all original Piaggio parts, which for a simple "refresh", gives a touch of panache to the motor with moderate treatment like that offered by our Ø63 thermal unit, ref. 3118005, which does not require any further modification.

The seats are designed to accept the original crankshaft bearings and oil seals (not supplied). V-One can be fitted with the original Dell'Orto Si 24-24 carburetor, in particular the assembly of the mixer is easy and made possible by the special support pin included and already fitted. It is possible to use the original crankshaft or our rotary valve crankshaft with 57 mm stroke ref. 5317510. Whatever the choice, the power supply has nevertheless been reviewed and implemented thanks to our CAD systems which have profiled an intake duct in the optimized crankcase.

Malossi decided it was time to turn the page to create an iconic component for such an iconic vehicle as the Vespa PX 80/125/150! Using all the technology and knowledge acquired on roads and tracks around the world, Malossi has developed the new V-One and VR-One crankcases. The design, study, research and production of these crankcases are the means by which Malossi intends to pay tribute to the fans of these vehicles. Both models offer the possibility to preparers, repairers and, more generally, all owners of a Vespa PX 80/125/150 to give free rein to their imagination and choose the modifications best suited to their requirements: L hobbyist, repairer, traveler looking for a part that can perfectly replace the original one, requiring no modification of the vehicle and offering a maximum choice of original parts among the main items on the market, will have at their disposal the V-One SPORT crankcase.

The preparer, looking for maximum performance, the best internal fluid dynamics and a greater possibility of engine development can purchase the VR-One MHR crankcase

TECHNICAL CHARACTERISTICS

Entirely made in ITALY

The technical and technological progress of Malossi is the greatest strength of our products, which is why we are convinced that we have manufactured one of the best crankcases ever produced.

Strength points

On every square millimeter of the engine crankcase is perceptible the innovation that jumps to the eyes of the most inexperienced preparers. Gravity die-casting, which differentiates these crankcases from the original models obtained, on the other hand, by a die-casting process combined with the use of modern cores in the shell-casting, results in better internal shapes and extreme precision.

Gravity casting allowed us to strategically increase the sections in the most stressed areas and to subject the crankcases to an improvement treatment after casting, thus obtaining a very high mechanical resistance. These products are made from a very high quality Al Si 7 Mg light aluminum alloy (EN AB and AC 42000) containing the exact amounts of: Silicon, to increase mechanical resistance, Manganese, for better resilience and corrosion resistance, Copper and Magnesium, to improve machining qualities.

The machining of the engine housings is entirely carried out in our workshop with the CAD / CAM process and in high precision CNC machining centers. All support and closure surfaces have been machined with diamond tools capable of ensuring very low surface roughness values and virtually perfect joints.

In both models there are pins for the brake shoes, which are installed directly at the factory by presses capable of applying the forces necessary to achieve the assemblies requested by our designers. In addition to the brake shoes, the engine housings are supplied with M7 studs required for mounting the gear selector. Finally, no version excludes the original electric starter, the control of which can be mounted in the appropriate plane formed in the cooling volute. The assembly of the crankcase on the vehicle does not require the purchase of any additional components, indeed, the two versions are equipped at the same time with a Silentblock at the front with the arm fixing to the hull, that with a anti-vibration rear attachment to the shock absorber. Fluid dynamics have finally been implemented! After having fitted our standard models with well-profiled ducts and good dimensions for a perfect assembly to our Ø68.5 cylinders, without excluding the possibility of installing other thermal groups and even by increasing the performance with these, relieves the preparers the obligation to work on engine casings to assemble more efficient cylinders. M7 studs for cylinder mounting are also included in the box!

Thanks to the interventions listed, obtaining higher powers is no longer a problem. Even the usual inconvenience of crankcase oil leaks has been solved with:

Increase in the walls of the pump housing, which also contributes to the mechanical strength of the housing

Using M8 studs instead of the old M7s

Extremely precise treatment of the closing surfaces. We removed the crankcase gasket, which was deteriorating and was the main culprit in the oil leaks. Now the housings are perfectly matched and sealed with joint compound, resistant even to the highest operating temperatures!

We didn't want to stop there! After years of assembling and disassembling original housings, modifying them and trying thousands of solutions to deliver constantly updated parts, we encountered inefficiencies and drawbacks that we analyzed to come up with our solutions: this is the case with the casing tightening system, which in the original parts is manufactured with the classic screw-nut system, notoriously impractical and not very easy for the user.

Such a valuable vehicle deserves the best possible maintenance, which implies the need to assemble and disassemble the various components to replace them or even to verify the correct functioning, by an overhaul if necessary. Anyone who got their hands on the original crankcases without disassembling the block from the vehicle has certainly encountered the difficulty of handling the parts that make up the block because of the uncomfortable and inaccessible position of the nuts, which, when unscrewed, risk falling to the ground and getting lost. Our solution is as simple as it is sophisticated: eliminate the nuts!

By making the threads in the left case (or transmission case) and the seats in the right side (or starter case), we have eliminated the need for nuts to tighten the two parts. To prevent the screw from accidentally being impacted or damaged during operation, with the risk of damaging the thread, we have, as far as possible, placed the right side of the seats in such a way as to allow complete removal of the seats. screws and keep them away from any danger.

Mounts on :

VESPA PX 125 2T euro 0-1

VESPA PX 125 2T euro 2 (VLX2M)

VESPA PX 125 2T euro 3

VESPA PX 150 2T euro 0-1

VESPA PX 150 2T euro 2 (VLX2M)

VESPA PX 150 2T euro 3

VESPA PX 80 2T

Reference: 486081

Ideal in case of wear and vibration or for a refurbishment of your machine.

Reference: 24303000

Very good quality SIP engine casing for old VESPA 2Ts.

Reference: 521312

Ideal in case of wear and vibration or for a refurbishment of your transmission casing on a PIAGGIO scooter.

Reference: 24301000

Engine casing SIP , EVO specific model with rotary intake for Vespa 50-125/PV/ET3/PK50-125/S 1°.

Reference: 5718382

MALOSSI high performance casings for VESPA 2T, model with valve admission!

Reference: 70350000

Replacement bearing for flywheel side secondary shaft on your scooters!

Reference: 5718392

MALOSSI high performance casings for VESPA 2T, specific model with rotary admission.

Reference: 90010000

SIP PREMIUM clutch side crankshaft bearing 25x62x12 mm for Vespa 125 V30-TS/150 VL-Super/160 GS/180 SS/Rally/PX80-200/PE/Lusso/T5/Cosa .. .