Reference: 0815850E

Pair of silentbloc Ø24 x 10,5mm for casing MALOSSI C / RC-ONE

Ideal for breakage or wear.

PEUGEOT 103

PEUGEOT 103 MBK 51

MBK 51 MOTOBECANE

MOTOBECANE PIAGGIO CIAO / VELOFAX

PIAGGIO CIAO / VELOFAX PEUGEOT FOX

PEUGEOT FOX HONDA CAMINO, PX, PXR...

HONDA CAMINO, PX, PXR... DERBI VARIANT

DERBI VARIANT.png) SOLEX

SOLEX PUCH

PUCH MINARELLI AM6

MINARELLI AM6 Low-pass exhaust pipe

Low-pass exhaust pipe High-pass exhaust pipe

High-pass exhaust pipe DERBI Euro 3 / 4 / 5

DERBI Euro 3 / 4 / 5 DERBI Euro 1 & 2

DERBI Euro 1 & 2 MINARELLI P4 & P6

MINARELLI P4 & P6.png) MINARELLI RV6, RV5, RV4, RV3

MINARELLI RV6, RV5, RV4, RV3 SUZUKI SMX, RMX, TSX

SUZUKI SMX, RMX, TSX YAMAHA TY, RD, DT, MX

YAMAHA TY, RD, DT, MX HONDA MB, MT, MTX, MBX, NSR R

HONDA MB, MT, MTX, MBX, NSR R YAMAHA CHAPPY

YAMAHA CHAPPYBanner

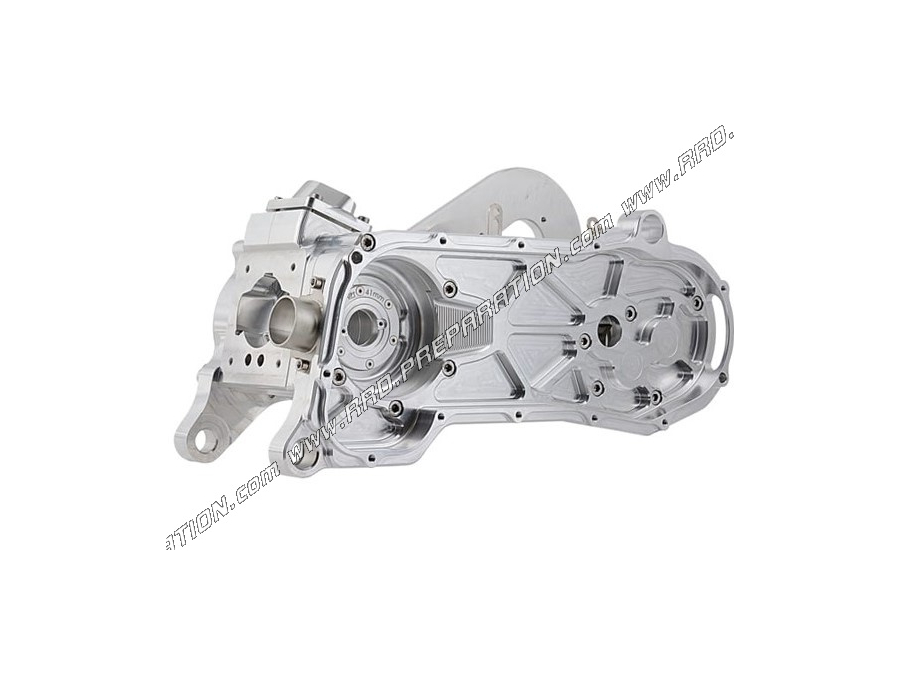

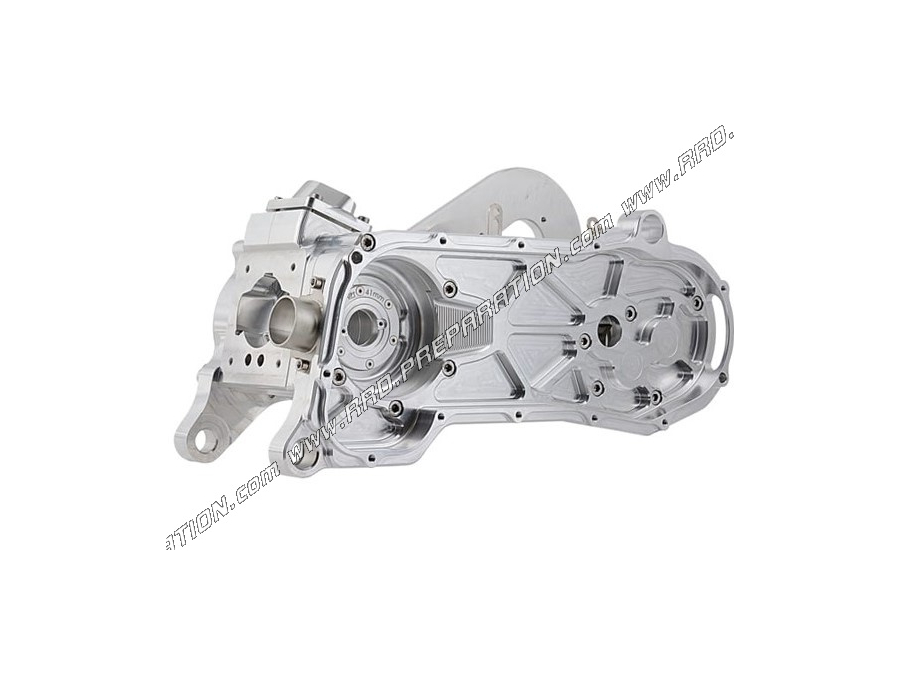

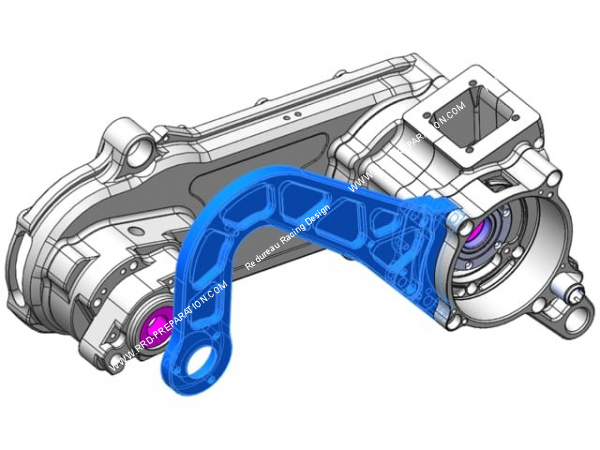

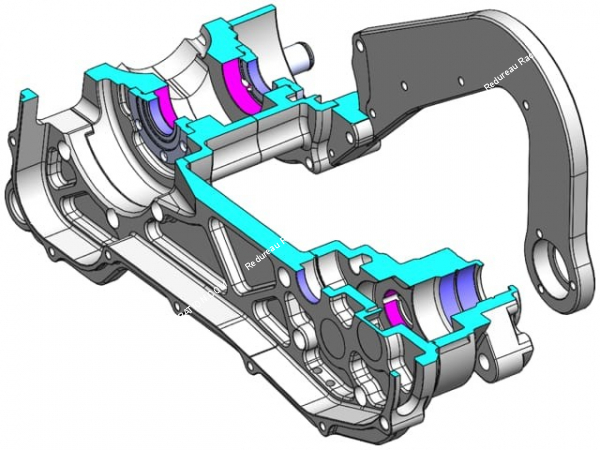

Made of anticorodal 6082 alloy (Al-Si-Mg-Mn alloy)

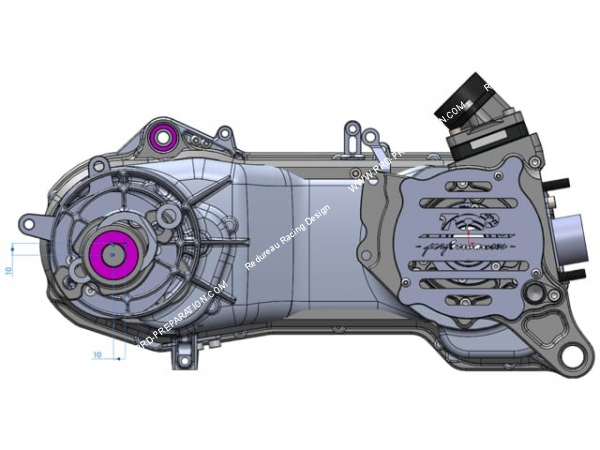

Pump body dimensioned for the installation of crankshafts with stroke up to 47 mm with connecting rod center distance 95/96 mm, without any additional intervention.

Ignition housing cut specifically for the ignition of the internal PVL rotor.

The use of the electric cooling pump, to eliminate the power absorption of the traditional mechanical pump.

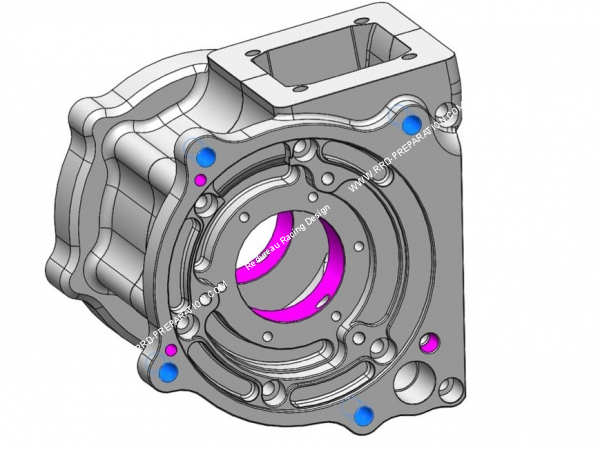

Enlarged and enlarged bearing seats with special features

Oversized coolant passage sections

VERSIONS AND COMPATIBILITY

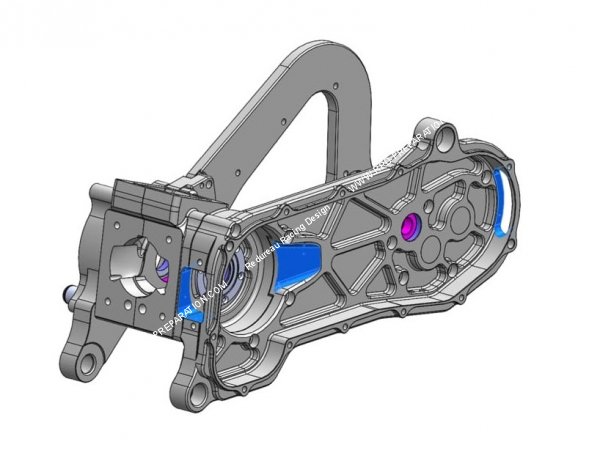

With this case, we can exchange:

• Half-cameras (70cc / 100cc / prototypes)

• Single arm (long / short)

• Braking system (disc / drum)

• Model (Piaggio / Minarelli)

Available versions:

• Piaggio 70cc. 99CRPT0700

• Piaggio 100cc. 99CRPT1000

The wheelbase has been extended by shifting the position of the wheel axle by 10 mm towards the rear axle and by 10 mm towards the asphalt. This solution improves the chassis and allows the rear shock to be used with a length of 10 mm less, reducing the inclination of the power supply and the casing.

TRANSMISSION LENGTH AND GEARS ARE UNCHANGED (possibility to mount any brand)

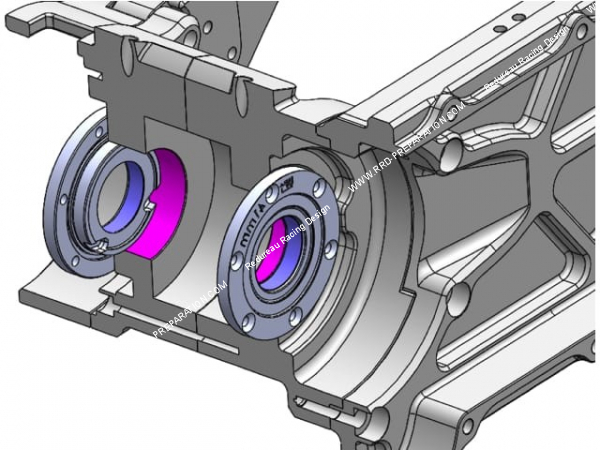

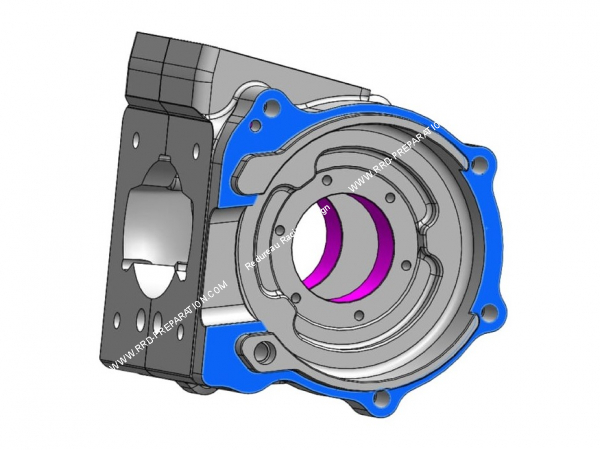

The gearbox has been radically innovated, introducing increased pitch. It was overturned with an opening to the outside, which eliminates the cover of the gearbox, improving the precision of the coaxiality, moreover an O-ring guarantees an optimal sealing.

TRANSMISSION LENGTH AND GEARS ARE UNCHANGED (possibility to mount any brand)

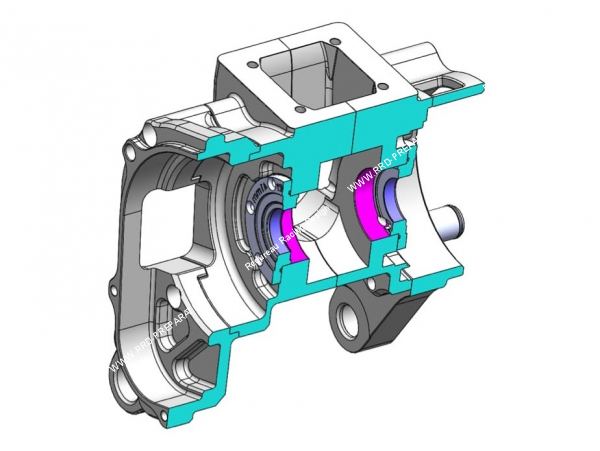

The oil seal housing now has two flanged bearings, which allows the two bearings to be reamed in one operation, as well as the cylinder support surface, achieving concentricity and absolute diametrical tolerance of the two seats. By reducing the stress of the shaft on the bearings and by increasing the power and the flow.

Completely revised, the torsen now has the connection on a much more compact diameter, without acting on the exhaust holes (as is the case for all competitors). This allows for a much stronger connection and two calibrated pins are also provided for perfect alignment. In addition, the section of more than 14 mm is much more robust than the other proposals.

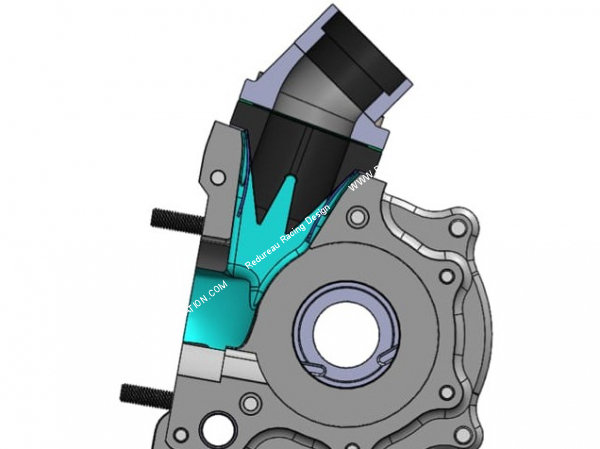

The air intake has been radically redesigned. In addition to being able to accommodate larger valves and carburetors, it also allows a better arrangement of the carburetor relative to the wheel. In addition, thanks to a double drilling model, it is possible to mount oversized valves and already used valves, with a central distance of 60x40 (for example AM6).

The ventilation of the transmission area has been clearly optimized. Many problems are caused by high temperatures; now it has two generous passages (entry and exit) and also a central extraction area for the drive. Possibility of installing forced flow rates on the incoming air inlet.

MAINTAIN THE POSSIBILITY OF ACCOMMODATING ANY TRANSMISSION (possibility of mounting any brand)

To date, no crankcase can boast such resistance in the crankshaft area. This section guarantees a more durable flatness and quality of the couplings. All processes are managed at a leading 5Assi palletizing center in the automotive sector and certified on measuring machines.

THE BEST SECTOR VALUE

MAINTAIN THE POSSIBILITY OF HOSTING ANY SHAFT AND TRANSMISSION

The structure of the report area has been increased thanks to FEM simulations. In addition to the increase in stress, we have considered the total adoption of bearings to improve the accommodation of relationships, by reducing misalignments of relationships that generate heat and reduce the power of the wheel.

Increasingly efficient engines require extreme safety in couplings. To date, the use of M6 fasteners on aluminum is undernourished and critical in the cases available on the market. We were able to redesign the entire housing with M8 screws for all couplings (with resistant section + 70% compared to an M6). This increases the stability and the level of security of the user.

An in-depth study to optimize the coupling between half-cameras and single-arm guarantees a stable and durable use. In addition to the centering and the phase, particular attention was also paid to the homogeneous distribution of the load of the screws, by positioning them in zones equidistant from each other and from the center, entirely of high strength high tensile steel, with cylindrical head and metric M8 thread.

Reference: 0815850E

Ideal for breakage or wear.

Reference: 152197

An original starter for quality refurbishment!

Reference: 99CRPT0700

Monstrous TPR FACTORY complete crankcase for PIAGGIO Liquid 70cc engine

Reference: 288639

Ideal in the event of loss or seizure of your transmission.

Reference: 28459

A similar oil pump originally but with a much lower price!

Reference: 99CRPT1000

Monstrous TPR FACTORY complete crankcase for Piaggio 100cc liquid engine

Reference: 5715844

An excellent competition cardr to build a beautiful engine!

Reference: 521312

Ideal in case of wear and vibration or for a refurbishment of your transmission casing on a PIAGGIO scooter.

Reference: 185004

Ideal for refurbishing your minarelli am6 gearbox.

Reference: 66473

Ideal in case of wear and vibration or for a refurbishment of your transmission casing on a PIAGGIO scooter.

Reference: 5717218

MALOSSI AIR FORCE transmission cover compatible with C-One crankcases, with RC-One and with the original Piaggio long crankcase

Reference: 285.0135

Ideal for the refurbishment of your part gear / transmission on casing MINARELLI & PIAGGIO.

Reference: 2514521

An excellent quality casing which reduces friction for less vibrations as well as better centering and wheel bearing!

Reference: 280.0055

Transmission needle socket for PIAGGIO scooter.

Reference: 478197 / AP8551031

Essential guide bush for your transmission.

Reference: 2615853E

Ideal for breakage or wear.